Capsule Filling - Why and How to Encapsulate Supplements

Learn about capsules and the benefits of encapsulation!

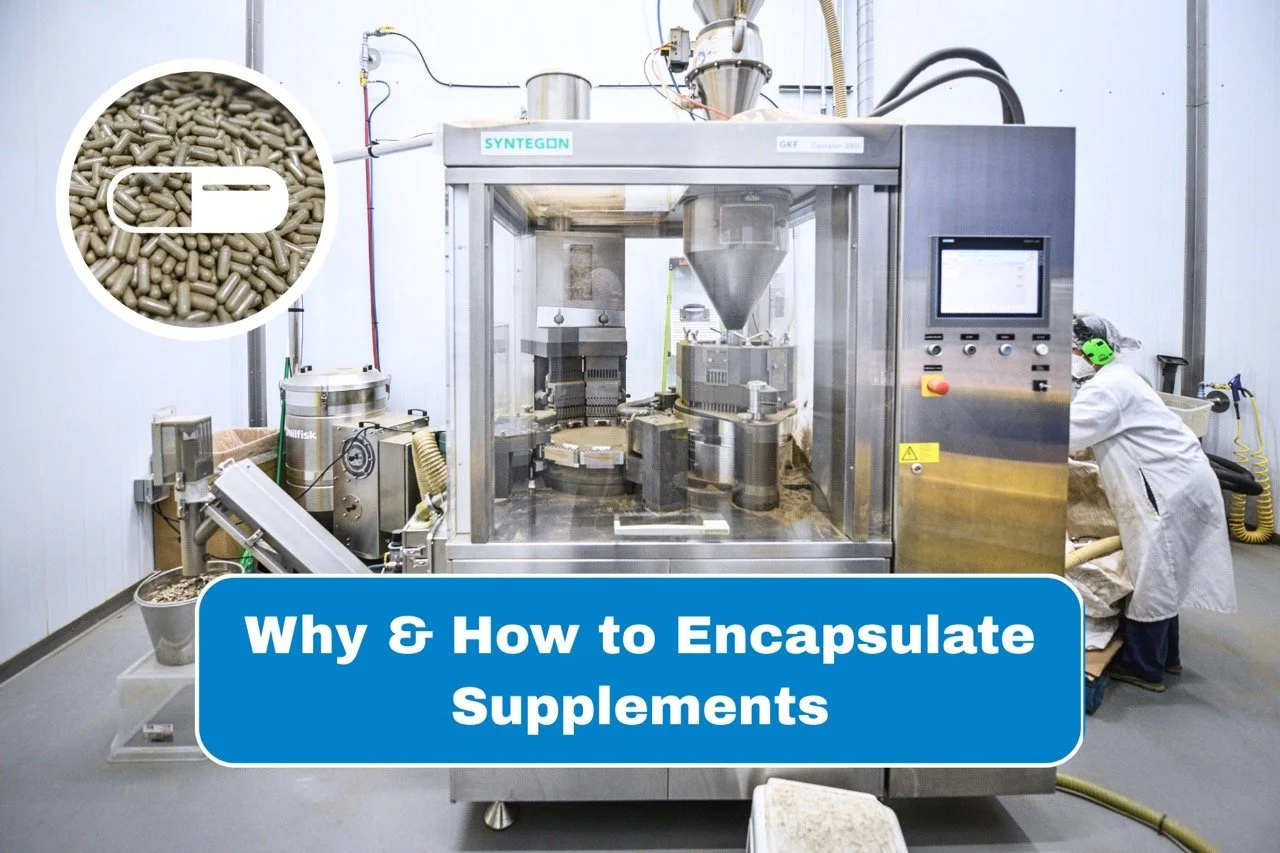

*Featured is Nutra Connection’s own encapsulation process and equipment.

Types of Supplement Delivery Systems

As part of the natural world, ingredients used to manufacture supplements degrade over time and may be susceptible to external factors such as light and oxygen. Because consumers expect their supplements to be potent and effective, product developers must determine the best delivery system for their product, whether it be a liquid, tablet, gummy, powder, or capsule. Choosing a good delivery system requires developers to consider what their ingredients can be manufactured into, which option will provide sensitive ingredients with protection from relevant external factors, and which option can maximize absorption of active ingredients. In each of these considerations, capsules have advantages that are worth exploring, so this post is dedicated to explaining those advantages and describing the encapsulation process.

The two main questions we’ll address in this post are:

What are the benefits of encapsulation?

How do you encapsulate supplements?

What are the Benefits of Encapsulation?

The dietary supplement industry adopted the encapsulation process pioneered by pharmaceuticals in the 1800’s. The adoption of this delivery system was so effective, in fact, that market research placed the value of the “food encapsulation” industry at 11.5 billion dollars back in 2022 - and projects its value to be 17 billion dollars by 2027! There is no doubt that encapsulation is a viable delivery system for developers looking to finalize a supplement product, but what are the benefits? Well, considering all of the different types of capsules and manufacturing/quality practices, the benefits may include…

Precise dosing

Ingredient protection

Formula stabilization

Flavor concealment

Controlled releasing (of active ingredients)

Longevity (later expiration dates)

Easy ingestion

To elaborate, because capsules act as a barrier against external influence, encapsulation may be of particular benefit when working with liquids, granular materials, or powders that are sensitive to light, oxidation, and/or moisture. This protection not only delays or prevents the degradation of your ingredients, it may also help to stabilize your formula, prevent consumers from tasting unsavory ingredients, and protect active ingredients during ingestion so they can be absorbed at the most effective time or place in the body.

Types of Capsules (Hard-shell vs. Softgel)

Before we can get into the process of encapsulating supplements, we’ll need to describe the two most common types of capsules: Hard-shells and Softgels. Hard-shell capsules begin as two halves of a whole, then are sealed together once filled with the proper dose of ingredients. Commonly referred to as “two-piece capsules,” hard-shells are made from gelatin* or HPMC** and can be filled with granular materials or powdered blends.*** To encapsulate liquids and oils, however, you’ll want to adjust focus to softgels, which are hermetically sealed and thus provide superior protection against moisture, light, and oxidation.

Due to Nutra Connection’s expertise on dry-blending and the encapsulation of powders and non-liquid materials, we will use Hard-shells in our explanation of the encapsulation process below.

*Gelatin capsules are bovine in origin, so they are not vegan or Kosher certifiable.

**HPMC stands for hydroxypropyl methylcellulose. Because the ingredients are vegan-friendly, these capsules are commonly referred to as “Vegicaps.” Nutra Connection recommends the use of HPMC to our clients, but we are also capable of filling hard-shell gelatin capsules.

***There are now LFHC’s (Liquid-Filled Hard Capsules) capable of storing liquid rather than just granular powders and blends, but they are less common and won’t be discussed in this post. Nutra Connection does not fill/use LFHC’s.

Hard-Shell Capsule Sizes

The last thing you should know before we delineate the encapsulation process is what size of hard-shell capsule to use. Your options - in order of largest to smallest - are 000, 00, 0, 1, 2, 3, and 4. Despite the large variety of initial choices, you can make the decision easier by picking from the two sizes most frequently used in the supplement industry, which are 00 (“double zero”) and 0. Both of these capsules have an excellent balance between internal capacity and ease-of-ingestion (swallowing).

00 —> The double zero capsule has an internal volume of about 0.95 ml, length of about 23.4 mm, and its cap’s external diameter is about 8.56 mm.

0 —> The 0 capsule has an internal volume of about 0.68 ml, length of about 21.6 mm, and its cap’s external diameter is about 7.64 mm.

The Encapsulation Process & Capsule Filling Machines

Once you have formulated and blended your supplement and have acquired the capsules you intend to fill, you can begin the encapsulation process. Whether filling capsules by hand, through automated equipment, or through a contract manufacturer, the fundamentals of the encapsulation process are the same:

Separate the capsule

Fill the capsule with powder

Tamper the powder down in the capsule

Close and seal the capsule

Polish the finished capsule(s)

These tasks may appear simple, but scaling the process can be difficult for some businesses. Although filling capsules by hand may be a feasible option for small production runs, it is much slower than automated filling and can introduce issues with accuracy, cleanliness, and labor costs. In stark contrast to manual filling, automated filling can quickly and accurately fill tens of thousands of capsules in less than an hour due to advancements in supplement manufacturing technology. Utilizing equipment that automates the encapsulation process can improve efficiency on small or medium production runs and is essential for completing large production runs. If investing in these automated machines too costly for businesses, they can still access them by working with contract manufacturers like Nutra Connection.

At Nutra Connection, we use a Capsylon GKF 3005 to encapsulate our client’s supplements. In conjunction with our capsule transfer system and powder reclamation system, we can output about 130,000 “double zero” capsules or 145,000 “zero” capsules in one hour with very little loss of powder compared to other manufacturers who lack the same equipment. We encourage the use of HPMC capsules, but our clients can request the use of gelatin capsules if they prefer.

Nutra Connection has a variety of manufacturing capabilities. Learn more about them on our Services page, here!

Nutra Connection’s Syntegon Capsylon GKF 3005 Encapsulation Machine

OUTPUT

00 —> 130,000 capsules per hour

0 —> 145,000 capsules per hour

Capsule Transfer System: Efficiently automates the process of transferring a container of empty capsules into the encapsulation machine’s hopper.

Powder Reclamation System: Picks up powder lost during the manufacturing process inside the machine, filters it, and re-introduces it. Minimizes loss of powder!